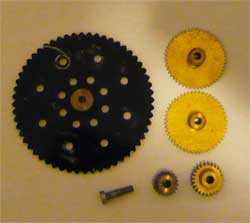

Mamod TE Spur Gear Differential

I had wanted to try this for a while, the latest mod I did turned out to quite a powerful tractor so thought it would be a worthwhile addition. It is based on one built by Fred Fox and described here, I decided to use Meccano gears and actually they worked out quite well.

|

|

How It Works The large sprocket drives a pair of bull gears, one on each side of it, through a system of three pinions. The outside bull gear floats and is attached to the rear wheel next to it. The inside bullgear is attached to the axle as is the wheel on the other side. The hardest part is to make the unit as narrow as possible, an extra 1/16" here and there can make a huge difference on a tractor this small. What I Started With

Getting Started

The next step was to split the face of the two pinions down the center, I then mounted the halves with the hub on a meccano shaft and shortened the length of the hubs as much as possible. The half of the # 25 pinion without the hub was attached to a 9/16" long length of Meccano shaft, I soldered it, would likely braze it in future. This was inserted from the back into one of the outer holes in the # 95b sprocket and the #26 pinion half with the hub was attached to the shaft stub, thin washers were used between the pinions and the surface of the sprocket.

The # 27 gear on the inside of the sprocket has to be mounted on the axle and fastened with a grub screw.The Meccono hub is not large enough in diameter to bore out to fit the 1/4" diameter shaft so I made a collar, sweated it over the existing hub, then drilled and tapped it for the grub screw. While I was doing this I did the same treatment to a Meccano bush wheel for the other side. A 1/4" diameter stub was attached to it to drive the wheel.

What I Learned Along the Way I used the parts I had on hand, I think if I did it again I would substitute # 27a gears instead of # 27 for the bull gears and use a combination of # 26 and 26c for the pinions. The 27a gears are already drilled and the hole that has to be drilled for the double pinions would not be so close to the existing hole in the large sprocket.

|